Here at C.D. Smith, we find immense value in working collaboratively with design teams, helping to achieve desired results and turn over quality buildings to project owners and clients. We view design and engineering teams as an extension of our own, promoting unity in vision, assisting in solving problems and communicating and sharing information freely. Below are a few ways we use technology in doing so.

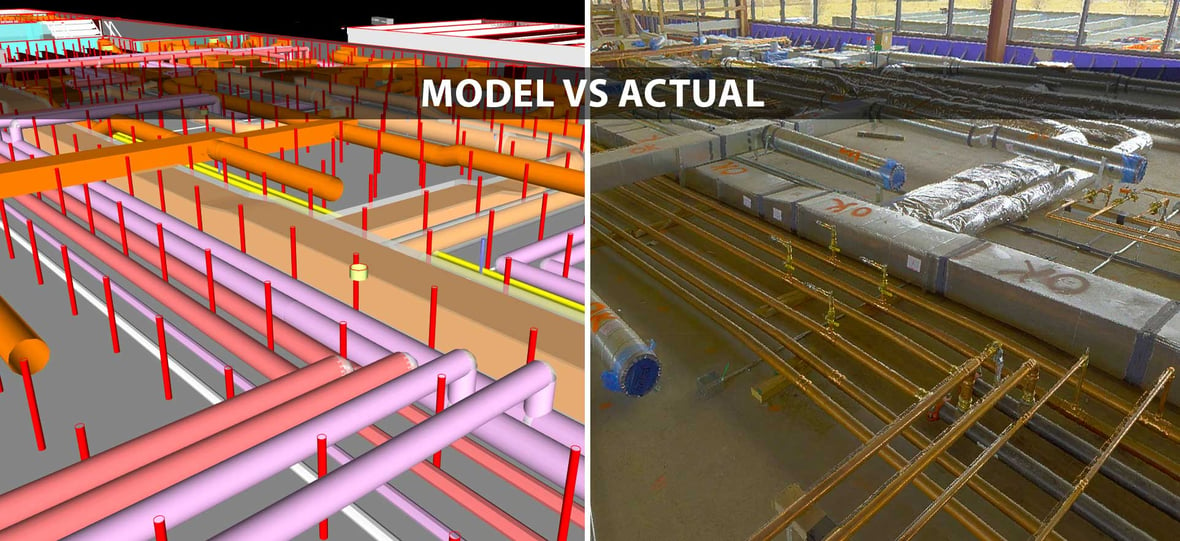

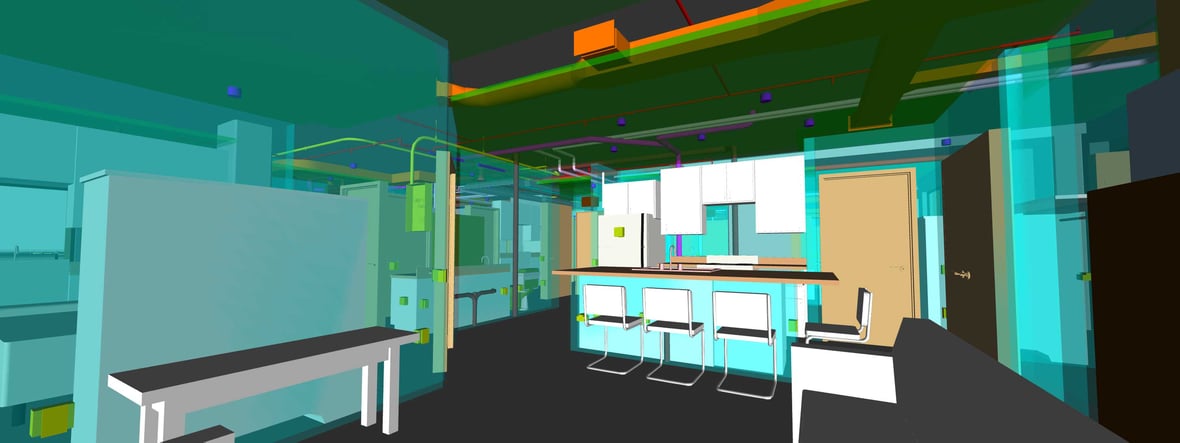

C.D. Smith’s VDC (Virtual Design & Construction) team utilizes building information models (BIM) to work collaboratively and efficiently while coordinating everyone’s scopes of work from design through installation.

C.D. Smith starts by working with the client and design team to define a BIM Execution Plan identifying roles and responsibilities required to deliver the project successfully. C.D. Smith leverages Autodesk’s BIM 360 platform to collaborate on cloud-hosted real-time models with the design team to identify and discuss project design options. Constructability reviews are performed during the design phase to mitigate unforeseen changes being needed and assess what information is still required to turn the design intent of the building into reality.

After the design is locked in, C.D. Smith leads trade coordination meetings with members of the design team to answer questions on the spot, minimizing time wasted on costly RFIs and ensuring any choices made maintain the quality building expected. Issues are tracked, and project constraints are logged and assigned for accountability. The project’s models transition/evolve into fully coordinated trade models that are signed off on for prefabrication and installation.

Benefits of VDC coordination during the design phase:

• Improve communication & collaboration

• Mitigate unforeseen changes

• Reduce errors, omissions & scope gaps

• Improve constructability

• Enhance cost control

• Ensure high-quality design is maintained

• Reduce the design team’s construction administration phase

Benefits of VDC coordination during trade coordination:

• Minimize RFIs

• Improve productivity & mitigate delays

• Reduce rework costs

• Reduce scope gaps and change orders

• Increase prefabrication, reducing field labor and increasing safety

• Improve sequencing & schedule

• Enhance project turnover package & quality building for the client

DURING PREFABRICATION

When Procore BIM (Building Information Modeling) is activated across our projects, owners can be active contributors during the design and contractor coordination process leading up to the fabrication of building components. It allows them to see the building design progress and ask for changes along the way. This creates a feasible and realistic tool for clients and the entire project team. Through Procore, the onsite team has one united drawing set and master model among all contractors, so everyone is building off the current coordinated design.

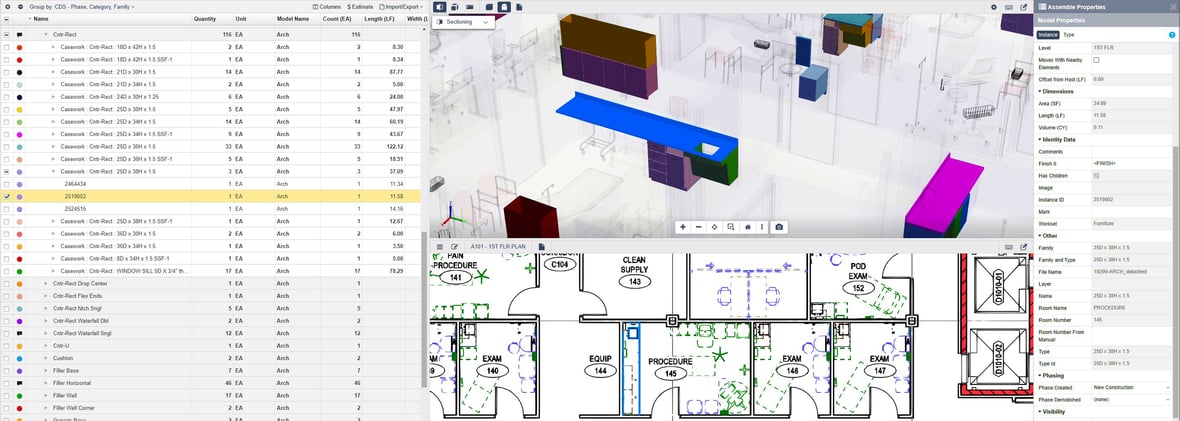

Tracking quantity changes via the models enables us to do iterative cost control, by identifying delta changes in material quantities weekly. This allows the design team to be kept informed for making incremental adjustments to keep a project within budget rather than waiting on milestone sets, resulting in making time-intensive design changes (value engineering and redesign exercises) to bring the project back within budget. This iterative cost control method avoids disrupting the design, schedule, and owner expectations by having a constant cost status.

What it is – C.D. Smith uses is a web-based, 3D model, quantity takeoff solution for visual tracking of quantity/cost changes on projects.

What it does - This enables us to do iterative cost control, by identifying weekly delta changes in material quantities on model updates. This allows the design team to be kept informed for making incremental adjustments to keep a project within budget rather than waiting on milestone sets.

What problem does it solve - Traditional workflows halt the process to gather a cost, oftentimes resulting in making time-intensive design changes (value engineering and redesign exercises) to bring the project back within budget, extending the design schedule and delaying the construction start date. This iterative cost control method avoids disrupting the design, schedule, and owner expectations by having a constant cost status.

Owner Benefits:

• Improved cost control via iterative estimating and delta change tracking executed in near-real-time

• Transparency/visibility of material quantity/cost changes

• Visualize the cost impact of design alternatives and value engineering options

• Improve decision making and collaboration between owner, architect and contractor

• Reduces surprise budget busts

• Reduces schedule slips due to redesigns and value engineering exercises

• Broadly accessible, user-friendly interface with no additional software required

WHAT IS LASER SCANNING?

A laser scanner captures the existing world using a laser and translates the data it receives into points (known as a point cloud). They also capture high-resolution, 360-degree images to map the points. This process is called reality capture. There are many uses for the point clouds including preconstruction planning, site verification, quality control and as-built documentation. But, for collaboration with the design team, we use it for existing conditions verification and design and trade coordination.

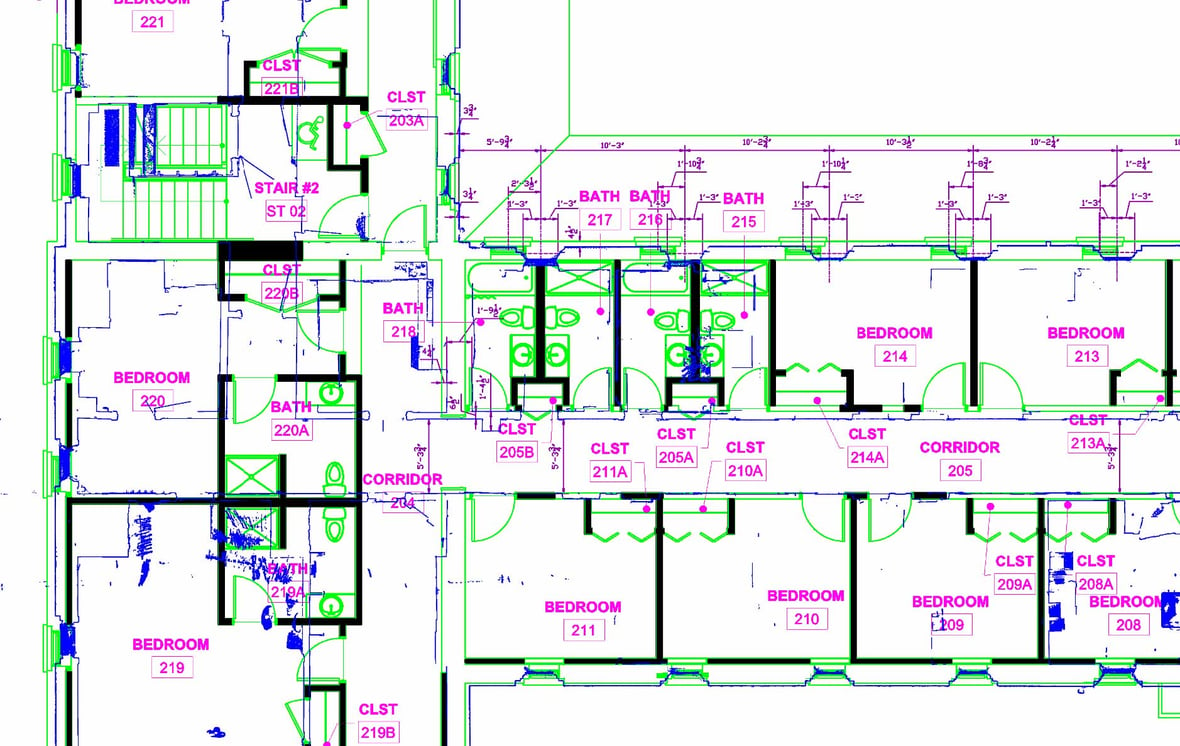

EXISTING CONDITIONS VERIFICATION

C.D. Smith can laser scan and compare a renovation plan against the actual site conditions, to verify that the new design works with reality, as the existing documentation may not reflect reality.

If we are on the project prior to the building design having been started, we can scan the existing building and set the laser scan up in Revit (typical 3D architectural design software) with plans, sections and elevations for the architect to have an accurate starting point for their new design. Highly accurate measurements can be taken and modeled by all design teams without the need to site verify conditions. This enables us to avoid disrupting areas such as sterile environments and factory floors more than once, minimizing any impact on client operations.

TRADE COORDINATION

In our effort to mitigate risk and reduce rework, we also use laser scans of existing spaces, MEPs and client equipment (e.g. assembly lines) to assist in the coordination of new work to be installed around the existing. We then work to avoid all collisions between the new building components and the ones that exist onsite.

About C.D. Smith

C.D. Smith Construction is an industry leader in safely providing the highest quality commercial construction services. Utilizing an integrated approach and self-performing trade services combined with technical expertise, our team serves as a solutions provider throughout all phases of a project, from planning through construction. With veteran leadership and a dedication to our employees and clients, we proudly place our name on projects of all sizes across the United States.

Visit www.cdsmith.com or follow us on Facebook, Twitter, LinkedIn, Instagram and YouTube.

Beneath the Hard Hat®, our company press and blog, offers an intimate look at the people and stories that make C.D. Smith Construction. With the latest industry news and project updates, we share insights on the superior spaces we are safely delivering year-round. Our team of technical experts provides useful tips and topics to help plan your next commercial project.

«•»

TRADE PARTNERS & BIDS |If you're interested in working with us or would like to request adding your company to our bidder’s database, please complete our Trade Partners & Bids Form: Click Here.

Corporate Headquarters

125 Camelot Drive

Fond du Lac, WI 54935

Milwaukee Office

8325 W. Tower Ave

Milwaukee, WI 53223

Madison Office

316 West Washington Avenue

Suite 900

Madison, WI 53703

La Crosse Office

333 Front Street North

Suite 701

La Crosse, WI 54601

Ready to build community and get connected with commercial construction expertise? Use the below form to submit questions or request information. We look forward to learning more and discovering how we can make YOUR PROJECT. OUR PRIORITY.®.

Privacy Policy | 2024 © C.D. Smith Construction, Inc.