Mass Timber construction is an energy-efficient alternative to high-rise and commercial buildings. Wood is a natural, renewable and sustainable material for building, with a lighter carbon footprint than steel or concrete. Not only does it have positive environmental impacts, but it has also proven to be structurally strong and meet the same performance and life safety standards as concrete and steel structures.

Mass timber materials are not inexpensive. However, mass timber offers several cost competitive advantages and long-term benefits. Columns, beams and panels on average weigh 1/5th the weight of concrete and steel materials, reducing shipping costs and requiring a smaller workforce to install. With prefabricated panels delivered directly to jobsites, construction time can be reduced by approximately 25 percent, saving owners even more time and money. Furthermore, wood structures have a biophilic effect on people, increasing occupants’ overall health and wellness and give long-term value to the design.

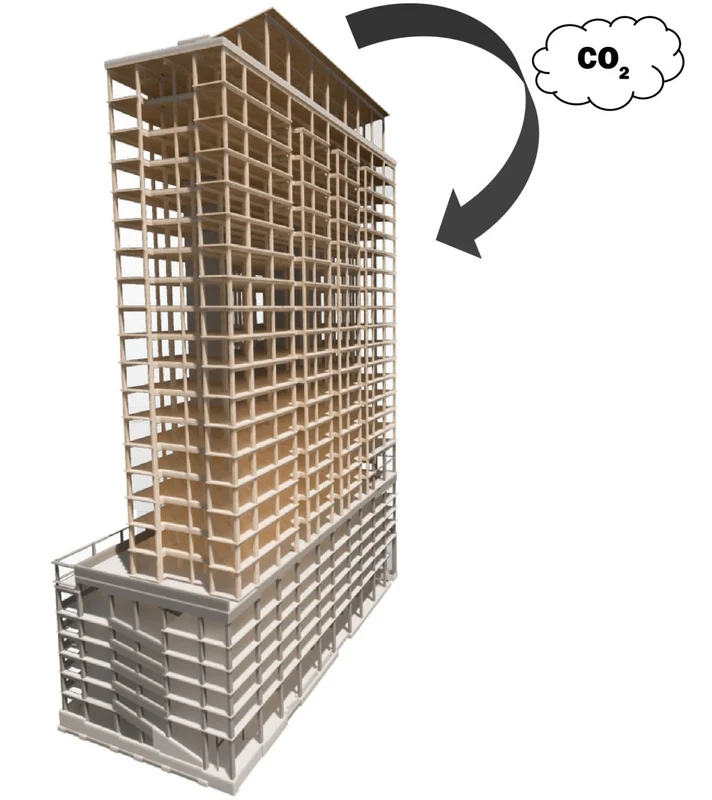

Timber buildings store carbon in their structure for the life of the building. An 18-story mass timber building, for example, has a negative carbon imprint equal to taking 2,350 cars off the road per year.

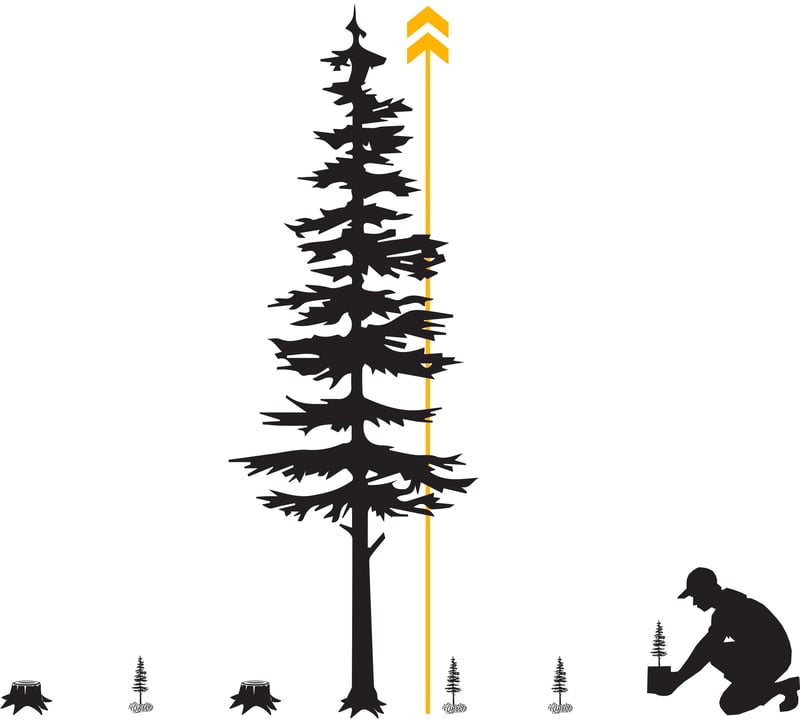

Modern forestry practices ensure a continuous cycle of growing, harvesting and replanting timber. Lumber that is sourced for mass timber construction is sustainably harvested using these best practices. Alternating trees are cut during harvest, allowing the remaining trees to grow twice as tall and not compete for natural resources. Additionally, when timber is harvested, two saplings are planted for every tree harvested, ensuring future forest growth and resources.

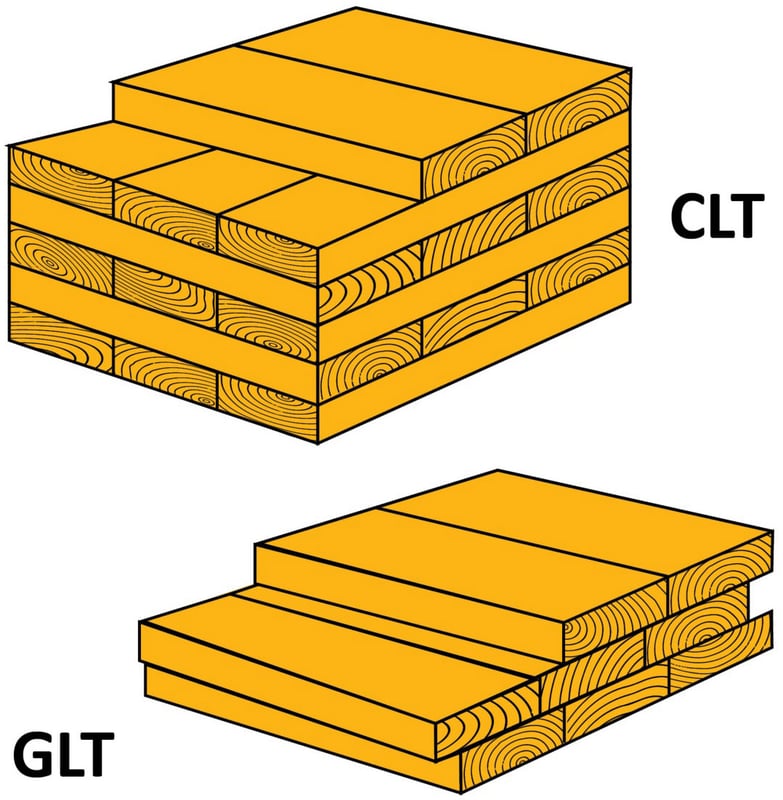

Mass timber comprises multiple solid, load-bearing wood panels bound together to create extraordinary strength and stability. Panels can be bound together through various methods, including nailing, gluing or using dowels. Depending on the desired structural integrity, compressed layers of wood will be stacked parallel or at 90-degree angles. While a fraction of the weight of concrete buildings, mass timber buildings can withstand seismic forces and embodied energy, including earthquakes and high winds.

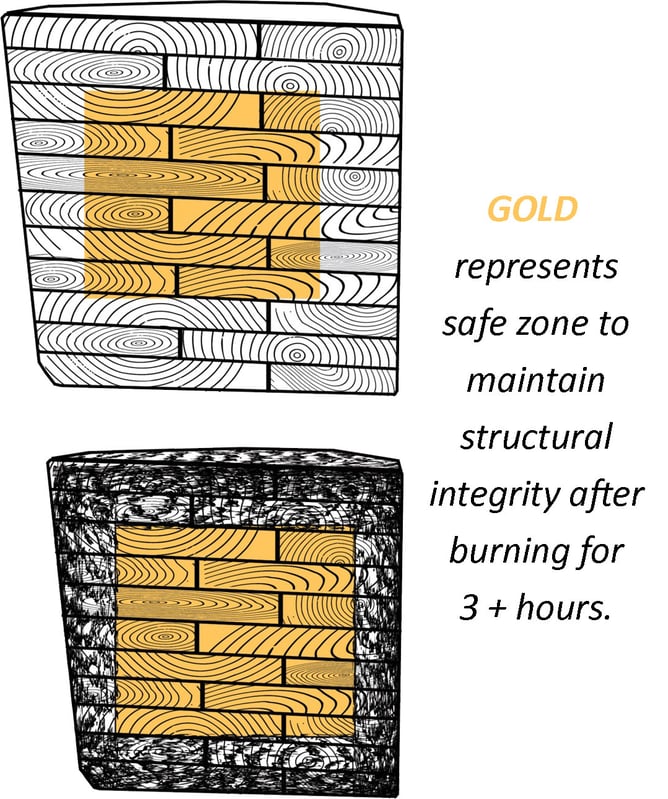

Mass timber columns, beams and panels are fire tested and rated to ensure occupant safety and meet building code requirements. Fire ratings are based on building types set by local and state building codes. Type I Buildings, commonly multi-story or high-rise buildings, require a fire-resistant rating of three hours. Timber burns in a predictable way, charring the wood’s exterior; this is called the char zone. Once a char-zone is formed in the event of a fire, it insulates the remaining wood, allowing it to retain its structural capacity. Engineers determine the required thickness needed to maintain the structural integrity of columns, beams and panels and add upwards of 16 inches of additional material to create a char-zone that would be burned off in the event of a fire. This structural design ensures it will be structurally adequate under fire conditions.

YOUR PROJECT. OUR PRIORITY.® | We'd love to hear from you and look forward to learning more for discovering how to build community by connecting you with integrated commercial construction expertise.

«•»

Mass Timber Project News

Mass timber: the future of construction? | 10.25.2024 FINANCIAL TIMES

(24 October 2024) | Ascent MKE, the world's tallest hybrid mass timber building, was featured in Financial Times' latest video "Mass Timber: The Future of Construction."

The recognition further highlights the global significance of the project and its contribution to sustainable urban development.

Key aspects of Ascent MKE:

1. Innovative Hybrid Design: Combining a six-story concrete base with 19 stories of mass timber, Ascent MKE showcases the versatility and potential of engineered wood.

2. Environmental Impact: The use of mass timber significantly reduces the building's carbon footprint, aligning with global sustainability goals and setting new standards for eco-friendly construction.

3. Fire Ratings: The project proved three fire ratings to qualify for Type I building, including: the horizontal floors and ceilings achieved a two-hour fire rating, the steel connectors achieved a two-hour fire rating, and the structural timber frame (glulam columns) achieved a world-first 3-hour fire resistance rating.

4. Economic Viability: Ascent MKE demonstrates that innovative, sustainable construction can be both environmentally responsible and economically feasible.

5. Rapid Construction: The use of prefabricated mass timber elements allowed for efficient on-site building assembly, reducing overall construction time.

Advancing the Industry

As highlighted in the Financial Times video, mass timber construction is gaining momentum globally. Work on Ascent MKE and other mass timber projects is contributing to a growing body of knowledge about mass timber construction, helping to shape the future of wood as a renewable and sustainable building material.

The Rise of Mass Timber: A Sustainable Building Solution For Wisconsin | Spring 2024 BENEATH THE HARD HAT®

C.D. Smith is leading the way in sustainable construction with their involvement in numerous mass timber projects, including Ascent MKE, the world's tallest hybrid mass timber building. These projects demonstrate the company's commitment to an innovative and eco-friendly approach. By embracing mass timber, C.D. Smith is helping to shape a greener future for the construction industry.

Milwaukee is the Center of Mass Timber Momentum | FacilitiesNet 09.27.2024

The Ascent, Milwaukee's tallest mass timber building, has redefined urban living. This innovative high-rise apartment complex not only reduces its carbon footprint but also streamlines construction. Milwaukee's commitment to mass timber is evident in its ambitious plans for the future, including multiple proposed mass timber towers and buildings in development. As more developers recognize the advantages of mass timber, Milwaukee's skyline is poised to become a showcase of innovation and environmental responsibility. For more information, visit the full article at https://www.facilitiesnet.com/designconstruction/tip/Milwaukee-is-the-Center....

Wisconsin's Wooden Skyscrapers | BELT Magazine 09.26.2024

Wisconsin is at the forefront of a sustainable building revolution. The state's mass timber construction projects, such as Milwaukee's Ascent, showcase the innovation and environmental benefits of this emerging technology. Mass timber offers faster construction, reduced carbon emissions, and improved indoor air quality.

While mass timber faces challenges like fire safety concerns and the need for responsible harvesting, its potential is undeniable. As Wisconsin continues to lead the way in mass timber adoption, it is paving the path for a more sustainable and resilient future. For more information, visit the full article at https://beltmag.com/wisconsins-wooden-skyscrapers/.

Building the Future: How Skilled Trades are Adapting to Mass Timber Construction | Spring 2024 BENEATH THE HARD HAT®

Discover innovations in mass timber high-rise construction from the collaboration between ironworkers and carpenters. Learn how skilled trades professionals are working together to build sustainable urban architecture.