Lean Planning

“Give me six hours to chop down a tree, and I will spend the first four sharpening the axe” is an iconic quote from Abraham Lincoln that we’ve all probably heard at some point in our careers.

When building the world’s tallest mass timber hybrid building, Ascent, the project team took a similar approach.

In this post, we’ll explore the importance of a few lean construction practices and planning principles that can be applied to any project.

By sharpening our axe, we can effectively and efficiently execute a project, deliver it on time, within budget and minimize waste and rework.

Preconstruction planning for Ascent began eight months before ground broke in August 2020. Early on, the project team understood that successfully building the world’s tallest timber tower would require a collaborative effort.

The level of preconstruction planning and coordination required was intense. Plans called for the mass timber columns, glue-laminated beams and cross-laminated timber (CLT) panels to be prefabricated offsite and shipped to the location for installation.

Prefabrication is an effective way to eliminate waste, focus on flow and optimize the overall project.

By taking advantage of prefabrication opportunities, significant cost savings can be realized while reducing the overall construction schedule.

However, the lead time for the overseas prefabrication and delivery was six months for the Ascent project. This needed to be accounted for in the master phased schedule.

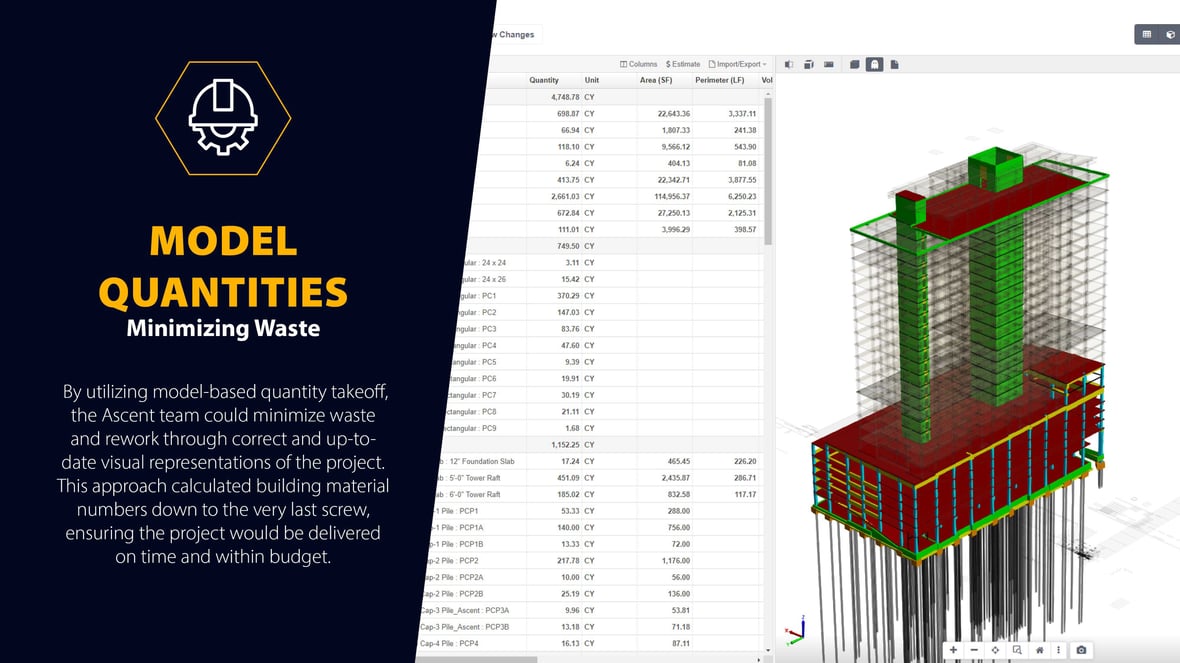

To add to the project’s complexity, all the mechanical, electrical and plumbing (MEP) penetrations needed to be completed offsite in the material fabricator’s shop. This required the team to think about the process with the end in mind, virtually coordinating and digitally measuring every opening.

Here’s where it gets tricky. The columns at the base of the building are significantly larger than those at the top. The mass timber columns get smaller as a function of the proportionate building load reduction as you travel vertically up the floors of Ascent. At the same time, the on-center distance between screws decreases as the overall dimensions of the column decrease.

The placement of the 16” screws needs to adjust on the posts to accommodate the smaller column while not running into another adjacent 16” screw on the same column.

The placement of screws on a column is a significant problem if you discover it during installation. If the columns were identically prefabricated with the drill holes set in the exact same location on every column, when it came time to install the columns, the screws would clash.

The clash would cause rework, RFIs, wasted product and lost time. By looking at every part of the project individually and having foresight, we can identify potential problems and prevent errors from happening on a project.

To avoid a prefabrication catastrophe on Ascent, cross-functional teams held 64 meetings, each over three hours long.

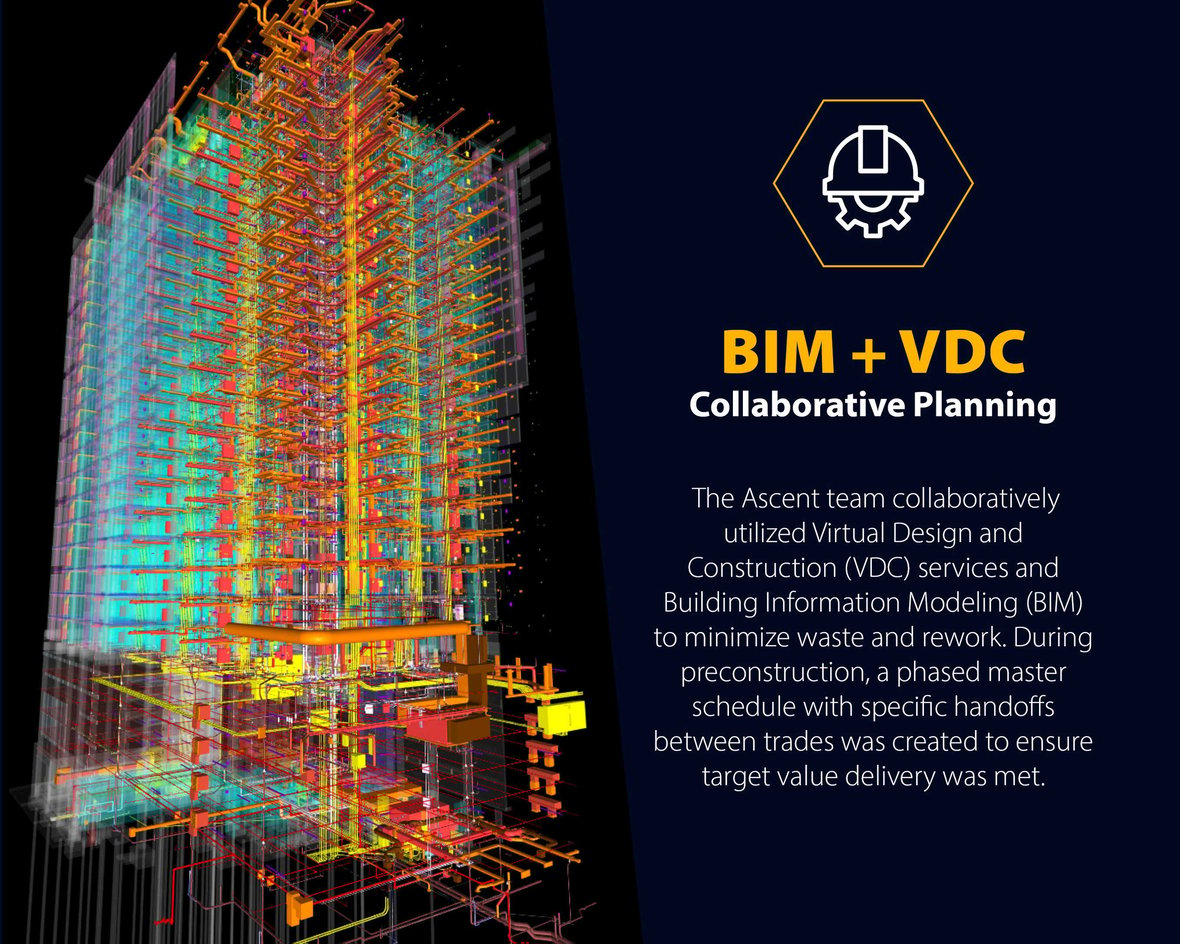

During these meetings, teams utilized Virtual Design and Construction (VDC) and Building Information Modeling (BIM) to identify potential clashes and create a phased master schedule with specific hand-offs between trades to streamline workflow.

By using collaborative meeting technologies and accessing interactive visual displays, design teams across the country and local cross-functional teams could obtain a unique perspective on the project and have a heightened understanding of the information they needed to guide the project successfully.

Accurate, detailed 3D visuals also helped production and installation teams during the construction process.

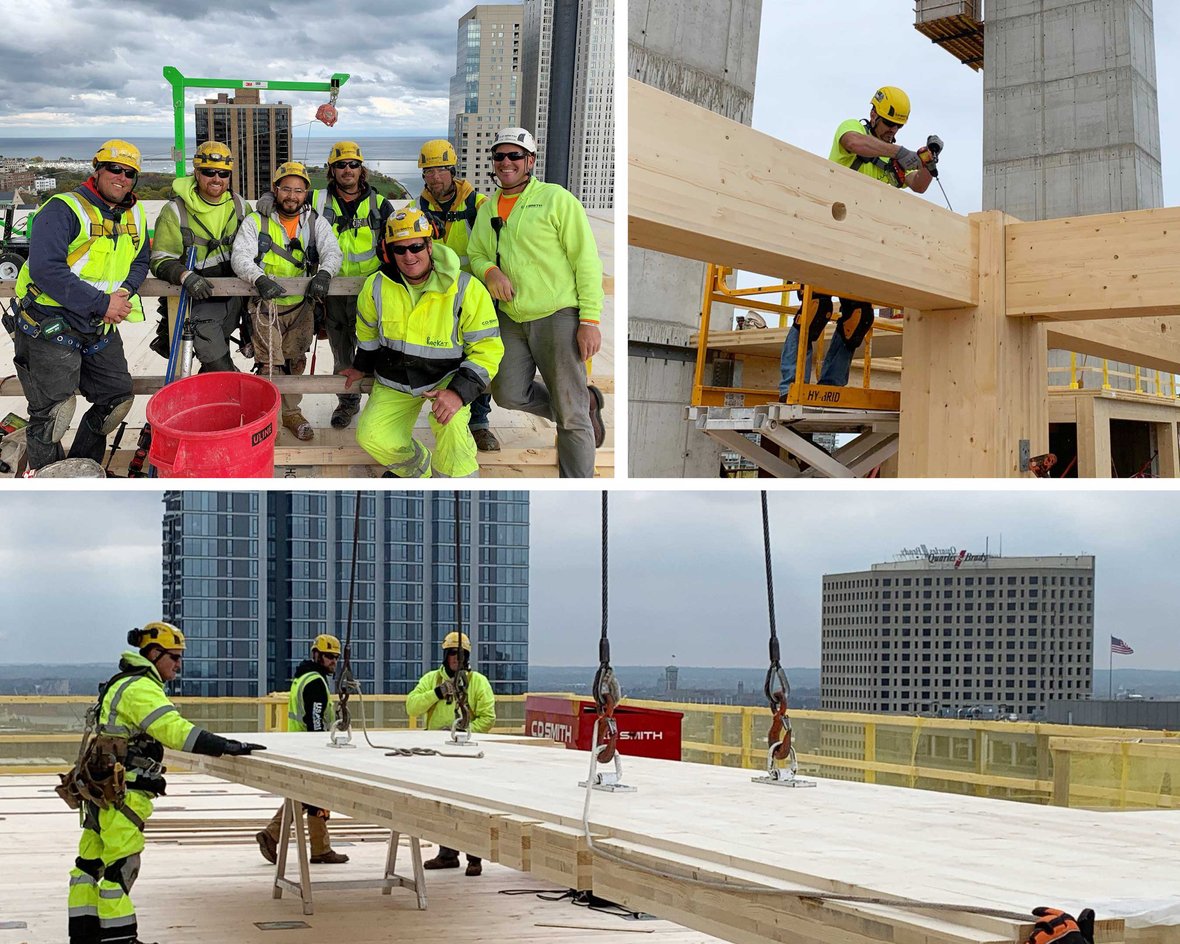

When it came time to erect Ascent, it was like a series of massive Lincoln Logs being assembled.

CLT panels were numerically placed in reverse order for shipping and transportation. Once they arrived at the jobsite, crew members could pull the panel they needed in the correct order without moving any other panels, streamlining the assembly process.

On the other hand, the column and beams were strategically packed to reduce transportation costs. Once they arrived onsite, crews came up with an idea to pick multiple bundles of columns and beams off the truck and then land them at a structurally engineered location on the deck for sorting and erecting. Then the crew could make mini picks from the bundles to set each column and beam.

When crews began assembling the first floors of Ascent, it would take 7-8 days to complete a single floor. With a culture of respect, crew members felt valued and excited to share ways to become more efficient. By the time they got to the seventh floor of mass timber, crews were hitting their stride and completing a floor every five days, cutting their time by nearly 40 percent!

If you look at the projects you are working on, are there opportunities to sharpen your axe before striking and apply a lean principle or two?

Focus on what your target delivery looks like. Then think about getting project partners involved early on and building common ground to execute a project successfully.

Through early team involvement, architects, engineers, construction managers, trades partners and material suppliers could collaboratively identify, address and bring this record-setting mass timber hybrid building to life.

Additionally, by fostering a culture of collaboration and respect for the individual, teams became more engaged, productive and innovative, which ultimately saved time and money on the final project delivery.

You get what you need, want | The Business News 10.24.2022

«•»

About C.D. Smith

C.D. Smith Construction is an industry leader in safely providing the highest quality commercial construction services. Utilizing an integrated approach and self-performing trade services combined with technical expertise, our team serves as a solutions provider throughout all phases of a project, from planning through construction. With veteran leadership and a dedication to our employees and clients, we proudly place our name on projects of all sizes across the United States.

Visit www.cdsmith.com or follow us on Facebook, Twitter, LinkedIn, Instagram and YouTube.

Beneath the Hard Hat®, our company press and blog, offers an intimate look at the people and stories that make C.D. Smith Construction. With the latest industry news and project updates, we share insights on the superior spaces we are safely delivering year-round. Our team of technical experts provides useful tips and topics to help plan your next commercial project.

---

TRADE PARTNERS & BIDS |If you're interested in working with us or would like to request adding your company to our bidder’s database, please complete our Trade Partners & Bids Form: Click Here.

Mass timber offers several cost-competitive advantages and long-term benefits. Columns, beams and panels on average weigh 1/5th the weight of concrete and steel materials, reducing shipping costs and requiring a smaller workforce to install. With prefabricated panels delivered directly to jobsites, construction time can be reduced by approximately 25 percent, saving owners even more time and money. Furthermore, wood structures have a biophilic effect on people, increasing occupants’ overall health and wellness and give long-term value to the design.

Our self-perform capabilities are a direct result of our talented team members' skilled trade career paths in the communities in which we live and work.

Corporate Headquarters

125 Camelot Drive

Fond du Lac, WI 54935

Milwaukee Office

8325 W. Tower Ave

Milwaukee, WI 53223

Madison Office

316 West Washington Avenue

Suite 900

Madison, WI 53703

La Crosse Office

333 Front Street North

Suite 701

La Crosse, WI 54601

Ready to build community and get connected with commercial construction expertise? Use the below form to submit questions or request information. We look forward to learning more and discovering how we can make YOUR PROJECT. OUR PRIORITY.®.

Privacy Policy | 2024 © C.D. Smith Construction, Inc.